TOPPANエッジの

温度管理サービス

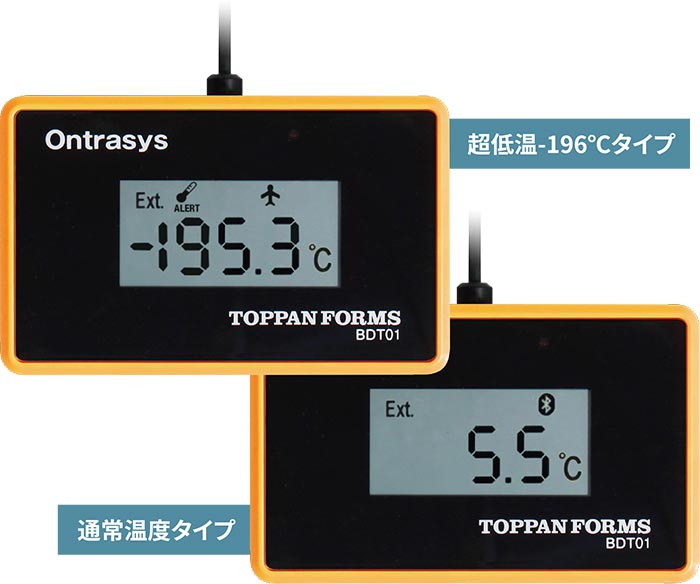

弊社が独自開発した温度管理プラットフォーム「オントレイシス クラウド」とRFID対応温度ロガー「オントレイシス

タグ」を組み合わせることで、輸送物・保管物の温度と位置情報を自動取得し、取得したデータの一元管理を可能にします。

医薬品や食料品を中心に安全性向上の取り組みと品質管理が求められている現在、医薬品のGDP※1ガイドラインに適合し、食品のHACCP※2に沿った温度管理で、物品の輸送・保管時の品質向上に貢献します。

- ※1 GDP(Good Distribution Practice)

- 輸送・保管過程における医薬品の品質を確保することを目的とした国際基準。日本は2018年12月末に厚労省から通達。

- ※2 HACCP(ハサップ、Hazard Analysis and Critical Control Point)

- 7原則12手順と呼ばれるガイドラインに従って食品を仕入れからお客さまに提供するまでを監視・管理する食品衛生基準。日本では2020年6月から義務化。

医薬品の適切な温度管理で GDP対応

GDP医療・医薬分野向けソリューション

HACCPに沿った定温管理で 食品安全を保つために

HACCP食品・流通分野向けソリューション